Better Data, Modular Solutions Drive Bergan Marine Systems

From inland towboats and tank barges, to oceangoing tankers and government fleets, Bergan Marine is literally everywhere you look on the waterfront. Kyle Durden, President & CEO, Bergan Marine Systems, discusses the rich history of this company; born in 1975 in Norway but operating from Florida since 1980, Bergan Marine Systems offers a full family of product and services that are connected, modular solutions that reduce installation and operating costs – ultimately providing better data.

When Kyle Durden reflects on his maritime career, the story starts where so many seafaring lives do — at the dock. Growing up in Port Aransas, Texas, a fishing village near Corpus Christi, Durden’s first taste of maritime work came early.

“My first job in high school was working as a deckhand on offshore fishing boats,” he recalls. “Early on, I had a deep appreciation for the sea and for the people who work on it.”

That early fascination turned into a lifelong calling. After hearing about Texas Maritime Academy (now Texas A&M University at Galveston), Durden enrolled — the only school he applied to — and graduated in 1986 with an engineering degree. Soon after, he went to sea with the U.S. Coast Guard, earning his chief engineer’s license at age 29.

“Those early years shaped my view of what mariners need and how critical equipment is in this industry,” he says. “That perspective has stayed with me throughout my career.”

Today, as President and CEO of Bergan Marine Systems, Durden leads a long-tenured and respected sensor and systems providers, a company that in 2025 celebrates its 50th anniversary.

Founded in Norway, Bergan Marine Systems relocated to Pensacola, Florida, in 1980, where it continues to design and manufacture mission-critical vessel systems for operators around the world.

“Fifty years in business is a long time,” Durden says proudly. “Today we operate a state-of-the-art manufacturing and engineering facility here in Pensacola, with a support center in Houston. We’ve got 44 dedicated employees designing, building, and supporting systems used on vessels worldwide.”

That small but specialized team punches above its weight. Bergan’s systems can be found on everything from inland towboats and barges to Navy auxiliary ships and offshore supply vessels. Roughly 30% of its work serves government and defense customers, while the remaining 70% focuses on the commercial market.

“This kind of diversification allows us to invest in our people, our products, and our technology,” Durden notes.

“We want to be that trusted provider of critical vessel information — whether it’s a tried-and-true tank level system or a next-generation IoT dashboard.”

“We want to be that trusted provider of critical vessel information — whether it’s a tried-and-true tank level system or a next-generation IoT dashboard.”

-Kyle Durden, President & CEO, Bergan Marine Systems

All images courtesy Bergan Marine Systems Another recent innovation is BargeWatch, a product developed hand-in-hand with operators. “It’s designed to make sure crews are alert and responsive during critical loading evolutions,” Durden says. “Think of it as BridgeWatch for the barge sector.”

Another recent innovation is BargeWatch, a product developed hand-in-hand with operators. “It’s designed to make sure crews are alert and responsive during critical loading evolutions,” Durden says. “Think of it as BridgeWatch for the barge sector.”

Delivering Critical Vessel Intelligence

At its core, Bergan Marine Systems has always focused on delivering critical vessel information — the data mariners rely on to safely operate ships and manage cargo.

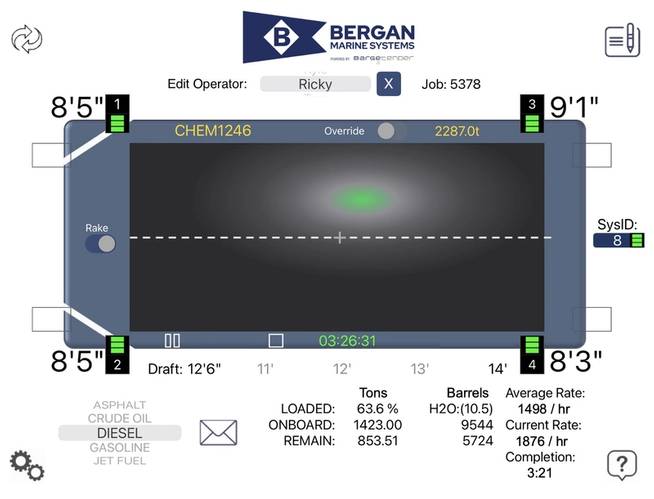

“Our systems tell crews what’s in their tanks, what their draft is, and all the information related to operational safety,” Durden explains. “Our catalog includes tank level indicating systems, overfill alarms, draft loading systems, and related hardware.”

The company’s equipment is found across the maritime spectrum — inland barges, tankers, offshore vessels, and government fleets alike. “Our bread and butter is still the tank level indicating system,” he says. “It’s what we’re best known for. But we’ve been expanding our line into digital and connected products to give customers more data and insight into their operations.”

In maritime, digitalization is more than a buzzword, rather a defining shift. And for Bergan Marine Systems, it represents a natural evolution of the company’s heritage in reliable sensing and control.

“Bergan Connect is our IoT-enabled platform,” says Durden. “It allows operators to access data like tank levels, cargo flow rates, fuel consumption, and alarm conditions from anywhere on any connected device.”

That capability is especially transformative for the inland barge market, long a digital outlier. “There are thousands of barges in operation in the U.S., but traditionally they haven’t been well connected,” Durden notes. “We’ve changed that. We’ve made IoT connectivity part of that ecosystem — even on vessels without constant power, using solar and battery solutions.”

Another recent innovation is BargeWatch, a product developed hand-in-hand with operators. “It’s designed to make sure crews are alert and responsive during critical loading evolutions,” Durden says. “Think of it as BridgeWatch for the barge sector. It gives managers real-time visibility into loading operations, allows remote troubleshooting, and reduces risk for the operator.”

Crucially, both platforms were designed with retrofit in mind. “We built these systems so customers can bring existing hardware into the digital age without a full system replacement,” he explains. “It keeps costs down while modernizing the fleet.” “Bergan Connect is our IoT-enabled platform,” says Durden. “It allows operators to access data like tank levels, cargo flow rates, fuel consumption, and alarm conditions from anywhere on any connected device.” Image courtesy Bergan Marine

“Bergan Connect is our IoT-enabled platform,” says Durden. “It allows operators to access data like tank levels, cargo flow rates, fuel consumption, and alarm conditions from anywhere on any connected device.” Image courtesy Bergan Marine

Safety Through Smart Tech

For Durden, safety isn’t just a selling point, it’s personal. His decades at sea taught him the risks mariners face, from heat stress to icy decks and rough-weather operations. “When I started sailing in 1986, the industry’s safety record was very different,” he recalls. “One of the systems we’re most proud of today is our draft loading system, which eliminates the need for crew to manually read draft marks painted on the hull.”

The system provides continuous, wireless draft data, allowing crews to load cargo to precise limits without stepping out on deck. “It maximizes load while minimizing risk — no one hanging over the side at night or in bad weather,” Durden says. “It prevents groundings and keeps mariners safe.”

Durden is also candid about how artificial intelligence is reshaping the way Bergan designs and supports its systems.

“When AI tools like ChatGPT came out, I was one of the early adopters,” he laughs. “I’ve always been interested in computers, and my son’s a programmer at LinkedIn, so I had a front-row seat.” Bergan now uses AI internally to improve software solutions and analyze electrical designs — but Durden sees its greatest impact coming in predictive analytics for shipboard systems.

“Our IoT dashboards already collect massive amounts of data,” he says. “Now, AI can detect anomalies that humans might miss — trends in the data that suggest maintenance issues or operational risks. It’s a game-changer for decision-making.”

He cites former Google CEO Eric Schmidt’s observation that AI could be “the most important invention in 500 years.” Durden agrees: “We’re just scratching the surface of what it will do for our industry.” The Draft Loading System is designed to enhance vessel safety. Image courtesy Bergan Marine

The Draft Loading System is designed to enhance vessel safety. Image courtesy Bergan Marine

Market Signals: Connectivity and Integration

Serving customers from inland barges to ocean-going tankers, Bergan Marine Systems is seeing strong demand for connected, reliable, and maintainable systems.

“As a former maintainer myself, I always look at our products from the deck,” says Durden. “Customers want systems that are easier to service, integrate seamlessly with other software, and provide better visibility into fleet operations.”

Integration and remote access have become central themes — especially after the pandemic. “During COVID, we couldn’t always fly engineers overseas,” he explains. “So we developed secure remote-access capabilities that let us tunnel into ship systems and troubleshoot sensor signals, even radar data, in real time. That’s now standard practice — better for our customers and a more efficient use of everyone’s time.”

Durden sees strong momentum in the U.S. maritime sector, particularly as government investment in shipbuilding and defense programs increases.

“The administration’s focus on revitalizing U.S. maritime infrastructure aligns perfectly with our capabilities,” he says. “Programs like the John Lewis-class fleet oilers at NASSCO have been a cornerstone of our business for decades. We’ve been on nearly every Navy auxiliary fleet class built there since the 1990s.”

Bergan is also providing systems for the U.S. Coast Guard’s new Polar Security Cutter, under construction in Pascagoula, Mississippi — one of several Arctic-capable ships now in the pipeline. “It’s exciting,” Durden says. “Any expansion in fleet capacity — commercial or defense — drives innovation, and that’s where we excel.”

As Bergan Marine Systems celebrates its golden anniversary, Durden insists the company is just getting started.

“We have a great legacy of products, and we’ll continue to support those customers,” he says. “But we’re also expanding our digital and connected systems — AI features, analytics, fleet dashboards.”

He pauses, then sums up Bergan’s mission simply: “We want to be that trusted provider of critical vessel information — whether it’s a tried-and-true tank level system or a next-generation IoT dashboard.”

Durden says collaboration will be key. “We’re teaming with new hardware and software partners and will be making announcements soon … it’s an exciting time.”

For a company that began with analog sensors and now delivers real-time, cloud-connected data from vessels worldwide, the transformation is remarkable. But Durden’s motivation remains unchanged:

“I started as a mariner,” he says. “Our mission is to support those mariners — to help them work safer, smarter, and more efficiently every day. We’ve been doing it for 50 years, and in many ways, we’re just getting started.”

Watch the full Maritime Matters podcast with Kyle Durden, President & CEO, Bergan Marine Systems.